Sanicleanse Air Teat Scrubber System

Pneumatic air-powered teat scrubber that can handle herds of all sizes

Introducing the Sanicleanse Air Teat Scrubber System – a game-changer in ensuring a consistent and efficient milking routine. The Air Sanicleanse model is powered by a pneumatic air motor, conveniently housed within the handle and driven by your farm’s existing air compressor. With no need for electricity, it runs 24/7, making it ideal for herds of any size.

Designed for reliability and ease of use, the Air Sanicleanse ensures dependable performance without the hassle of electrical connections, delivering a superior level of hygiene and productivity to your milking process.

How It Works:

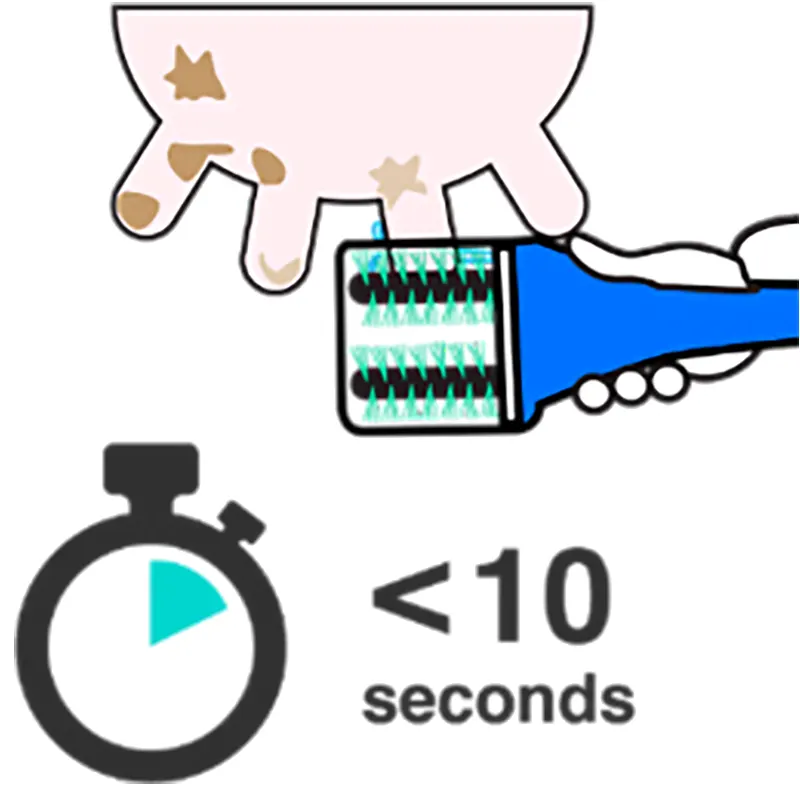

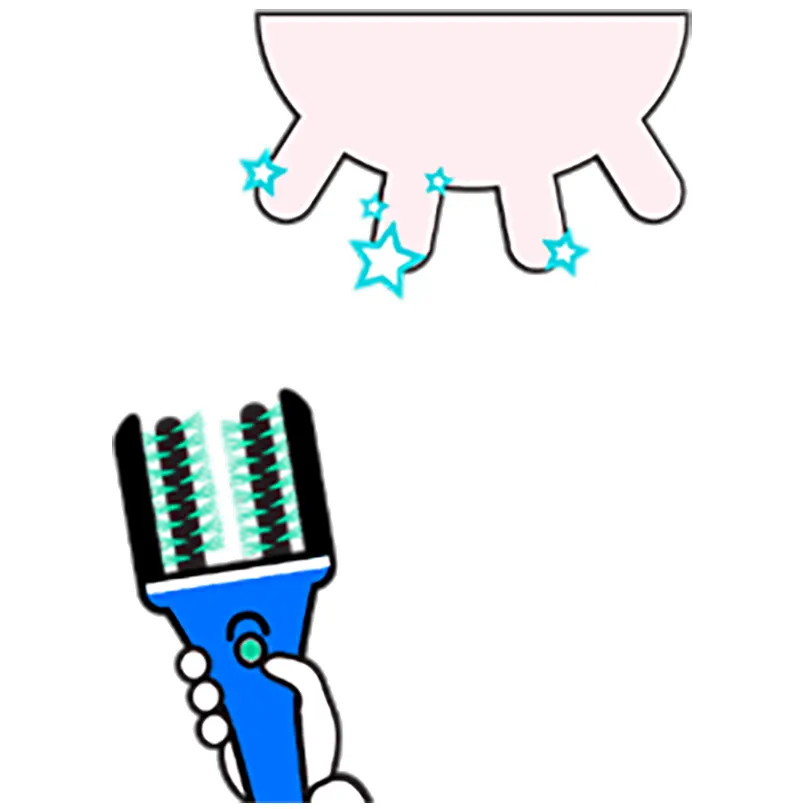

Phase 1: Warm Water & Chemical Mix • Purpose: Loosens dirt and debris while massaging the teat to stimulate milk let-down. • Bacteria Control: Kills bacteria on the teat surface for enhanced hygiene. Phase 2: Dual Brush Cleaning • Action: Two top brushes thoroughly clean and sanitise the entire teat, targeting environmental pathogens. • Additional Benefit: Stimulates the teat for faster milk let-down, optimising milking efficiency. Phase 3: Drying • Method: Brushes spin without liquid to dry the teat effectively. • Optional Feature: AirPrep system blows air around the teat for faster, more efficient drying.

Control Unit Options

Standard Control Unit: • Compatibility: Suitable for any parlour configuration. • Capacity: Option to control 1 or 2 teat scrubbers simultaneously. • Features: Internal keypad control with optional AirPrep air drying system. Touch Screen Management Unit: • Recommended: Ideal for larger farms (500+ cows). • Capacity: Can control 1 or 2 teat scrubbers. • Remote Access: Offers remote monitoring and management of brush usage, water, and chemical consumption. • Modes: Includes both manual and automatic operation modes. • Alerts: Low-level alert system for water and chemical levels. • Features: Integrated AirPrep air drying system for improved drying efficiency.